The Manufacturing Process of Crisper Mold

栏目:blog

发布时间:2021-07-13

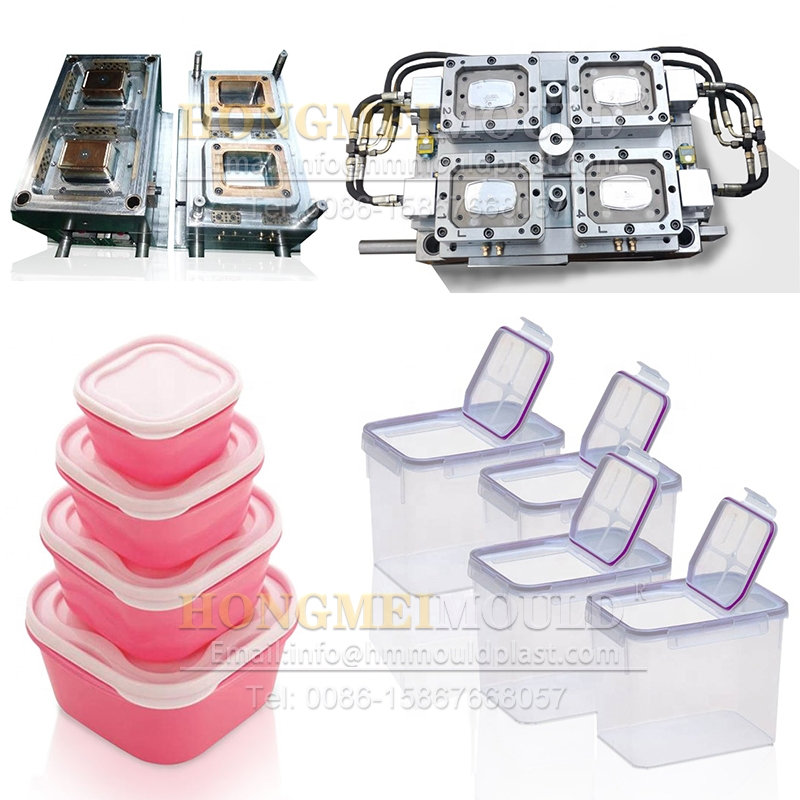

As a manufacturer of crisper mold with mature technology, Hongmei Mould has made 1-12 cavity crisper molds for customers. Moreover, the crisper products produced by Hongmei Mould have a glossy appearance and no burr, which are recognized by

The Manufacturing Process of Crisper Mold

As a manufacturer of crisper mold with mature technology, Hongmei Mould has made 1-12 cavity crisper molds for customers. Moreover, the crisper products produced by Hongmei Mould have a glossy appearance and no burr, which are recognized by many customers.Then let's learn about the manufacturing process of crisper mold.

1. The process analysis of plastic products.

Before the design of the mold, the designer should fully analyze and study whether the plastic products conform to the principle of injection molding processing. It is necessary to consult carefully with the designer of the products and reach a consensus.It includes the geometrical shape of the product, dimensional accuracy and appearance requirements, the necessary discussion, as far as possible to avoid the unnecessary complexity in the mold manufacturing.

2.Mold structure design.

A set of high quality mold, not only need to have good processing equipment and skilled mold manufacturing workers, another very important factor is to have good mold design, especially for complex mold, mold design quality accounts for more than 80% of the mold quality.A good mold design is in the premise of meeting customer requirements, so that the processing cost is low, the processing difficulty is small, the processing time is short.

3. Determine mold materials and select standard parts.

In the selection of mold materials, in addition to considering the accuracy and quality of the product, but also combined with the actual capacity of the mold factory processing and heat treatment to give the right choice.In addition, in order to shorten the manufacturing cycle, the use of existing standard parts as much as possible.

4.Parts processing and mold assembly.

Mold precision in addition to the design to give the best structure and reasonable tolerance fit, parts processing and mold assembly is crucial.Therefore, the choice of machining precision and machining method occupies a dominant position in mold manufacturing.

5.Test mold.

A set of mold from the beginning of the design to the completion of the assembly, only to complete its entire manufacturing process 70%~80%.For the error caused by the inconsistency between the predetermined shrinkage and the actual shrinkage, whether the demoulding is smooth or not, how the cooling effect is, especially the size, position and shape of the sprue on the precision and appearance of the product and other problems, must be tested through the mold test.Therefore, the test is to check whether the mold is qualified is an indispensable step to choose the best molding process.

Tel:0086-15867668057 Miss Libby Ye

WhatsApp:0086-15867668057

Wechat:249994163

E-mail:hongmeiLibby888@gmail.com