What are The Future Development Directions of The Mold?

栏目:newslist

发布时间:2021-06-11

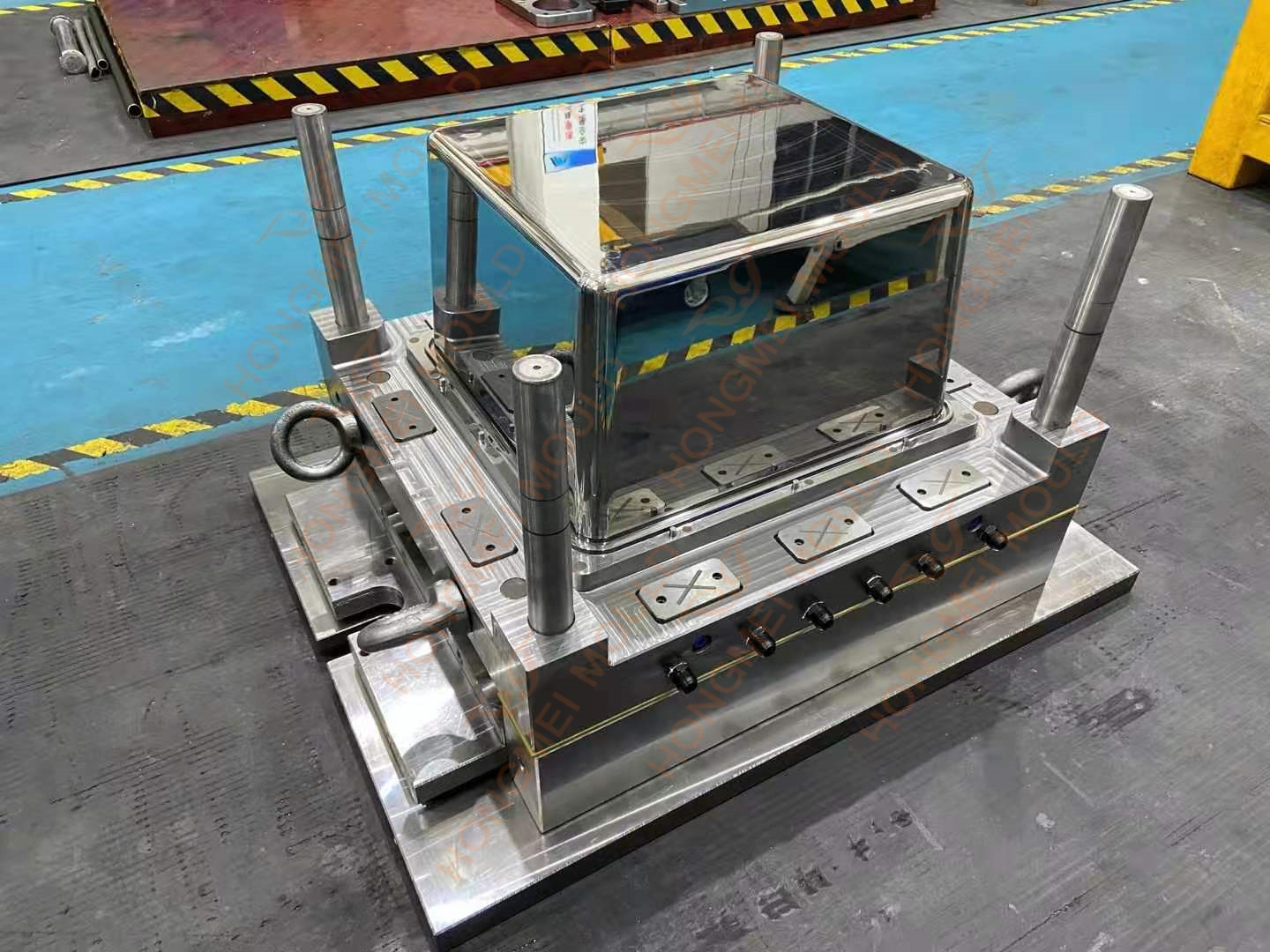

Mold is the mother of industry, is to make the product to achieve mass production, improve efficiency, reduce costs, is impossible to be eliminated in the industry.Especially in the current era of rapid development of China‘s industrializati

What are The Future Development Directions of The Mold?

In recent years, the mold industry is not so easy to do compared with the past.The fierce competition caused the price of mold orders to go down, and some people began to leave the industry.Here is a brief analysis of the evolution over the years.Mold is the mother of industry, is to make the product to achieve mass production, improve efficiency, reduce costs, is impossible to be eliminated in the industry.Especially in the current era of rapid development of China's industrialization process, the mold industry is still a sunrise industry, full of opportunities!The problem is that what Chinese mold owners need to process are low-grade to mid-grade molds, and there are not many high-end molds. It is believed that in the near future, the rise of China is unstoppable, the transformation of manufacturing industry is unstoppable, and the mold industry is naturally the same.After all, there is no high quality mold, is not to do high quality products.

1.High precision.

Whether the accuracy of the dimension can be achieved.The best in the past were Japan, Germany.With decades of continuous learning and innovation, our Chinese die and mould industry has also emerged a large number of companies specializing in high precision die and mould manufacturing.To do high precision mold, there are two main elements, one is equipment, one is talent.

2.High efficiency means high automation.

With the popularity of all kinds of automation equipment with mold production, as well as the improvement of the intelligence of the standard parts inside the mold, the efficiency of mold production is more and more high, and it will develop toward a higher and better realm.And in this process, the requirements for mold designers will be more and more high. At that time, mold designers can not only understand the automation equipment, but also participate in the design.In a highly mechanized future, the term "ordinary worker" will probably disappear.In the future, there will be only three kinds of people in factories: managers, technicians and robots.

3. The new mold is progressing with the technological innovation.

Many of the original needs of a very complex, very tortuous way to achieve the mold can be very simple.There are also many structures that were previously thought to be impossible that have become possible.These are the new opportunities and challenges of die and mould industry.To be specific, it is the opportunity and challenge for mold designers. Mold factories that have mastered these new mold design and manufacturing technologies will have more initiative.Mold, always depends on technology and quality of the industry!

4. The trend of product research and development and mold integration is also inevitable.

This change affects the manufacturing model more than the assembly line replacing the all-powerful mold maker.Simply put, is the mold design and product research and development into a new position, a can be responsible for the whole product from the appearance to the organization, and then to the mold, mold processing, mold production, product assembly a series of work of a new position.To become the absolute core of manufacturing.

Tel:0086-15867668057 Miss Libby Ye

WhatsApp:0086-15867668057

E-mail:info@hmmouldplast.com