Professional Plastic Stool Mold Manufacturer

栏目:blog

发布时间:2021-07-01

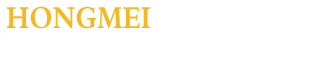

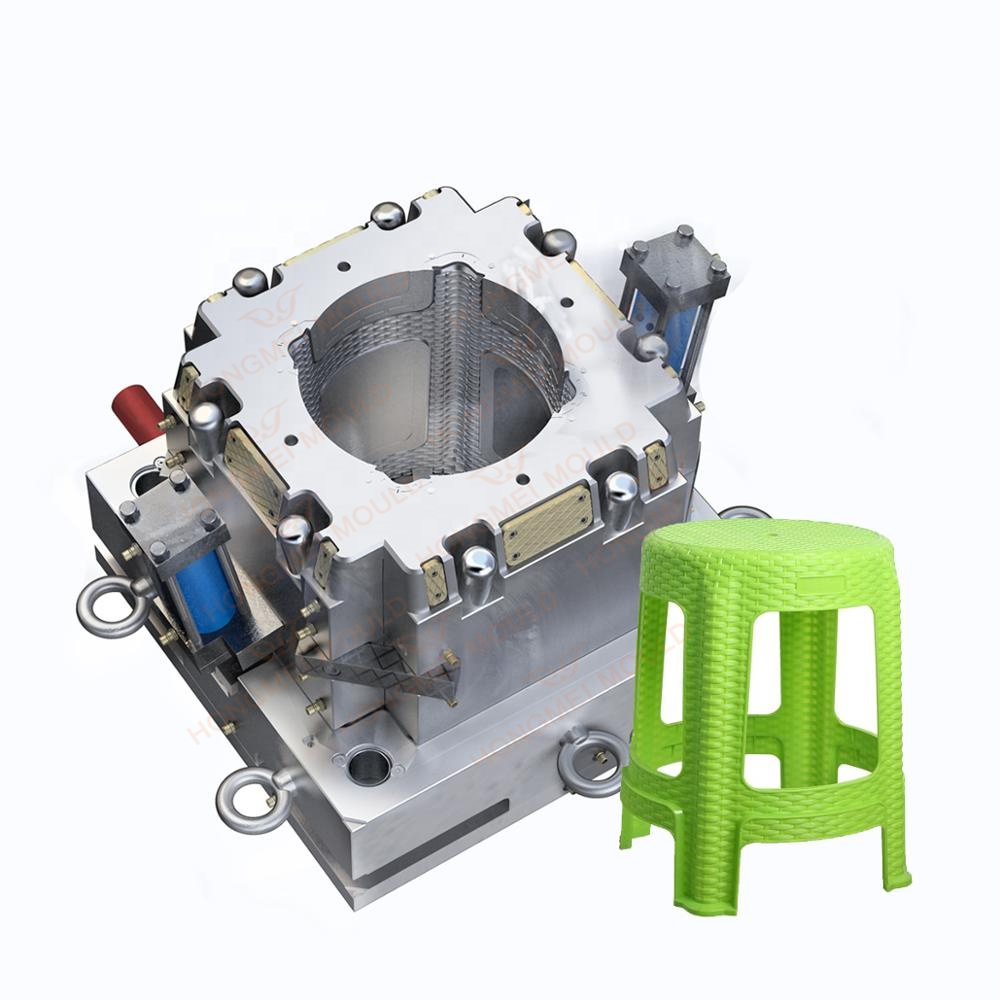

Plastic stool in daily life have a lot of application scenarios, because of the production of large batch, low price, PP material, durable, so it is very suitable for plastic manufacturers to invest in production.The goal of Hongmei Mould is

Professional Plastic Stool Mold Manufacturer

Plastic stool in daily life have a lot of application scenarios, because of the production of large batch, low price, PP material, durable, so it is very suitable for plastic manufacturers to invest in production.The goal of Hongmei Mould is to provide customers with high quality stool molds according to customer requirements.We constantly improve the mold design and manufacturing process to help customers with lower costs to achieve more efficient production capacity.

The following are some key points of the plastic stool mold made by Hongmei Mould:

1. Number of Cavities:

The number of cavities we design is usually 1 cavity

2. Cavity and Core Steel:

We provide a variety of stool die steel for customers to choose, such as P20, 718, S136, H13, # 45 and so on.High quality steel can effectively ensure mold life and product quality.

3.Heat Treatment:

We use different heat treatment technology for different steel to ensure better polishing and service life.After heat treatment, the hardness of the mold core and cavity can reach HRC 32-36.

4. Cooling System:

The circulating water of optimized design is adopted to improve production efficiency and greatly reduce production cost.

5.Mold Processing:

All parts are processed by CNC lathe, mold assembly work by engineers with more than 10 years of rich experience to complete.

6.Cycle time:

20-32s

1. Number of Cavities:

The number of cavities we design is usually 1 cavity

2. Cavity and Core Steel:

We provide a variety of stool die steel for customers to choose, such as P20, 718, S136, H13, # 45 and so on.High quality steel can effectively ensure mold life and product quality.

3.Heat Treatment:

We use different heat treatment technology for different steel to ensure better polishing and service life.After heat treatment, the hardness of the mold core and cavity can reach HRC 32-36.

4. Cooling System:

The circulating water of optimized design is adopted to improve production efficiency and greatly reduce production cost.

5.Mold Processing:

All parts are processed by CNC lathe, mold assembly work by engineers with more than 10 years of rich experience to complete.

6.Cycle time:

20-32s

Hongmei Mould will provide you with the best stool mold solutions, from the structure and shape design, molding process characteristics to help you develop novel and practical products to create market competitiveness.

Tel:0086-15867668057 Miss Libby Ye

WhatsApp:0086-15867668057

Wechat:249994163

E-mail:hongmeiLibby888@gmail.com

Tel:0086-15867668057 Miss Libby Ye

WhatsApp:0086-15867668057

Wechat:249994163

E-mail:hongmeiLibby888@gmail.com