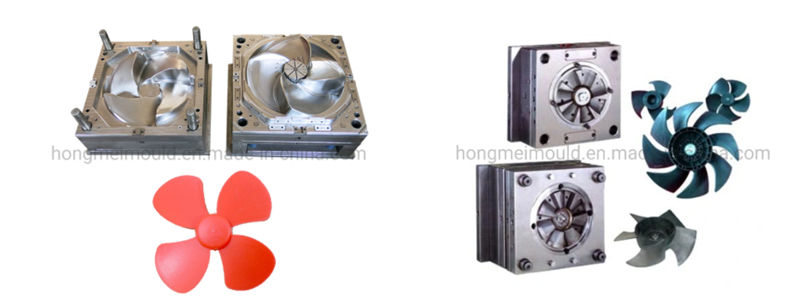

Mould Specification

Mould name: plastic fan blade mould

Cavity: H13

Core: H13 with beryllium bronze

Mould base: P20

Injection system: Yudo 6 valve gates

Cycle time: 20s

Mould size: 620x370x600mm

Suitable machine: 380T

Mould lead time: 35 days

Packing: Strong export wooden box

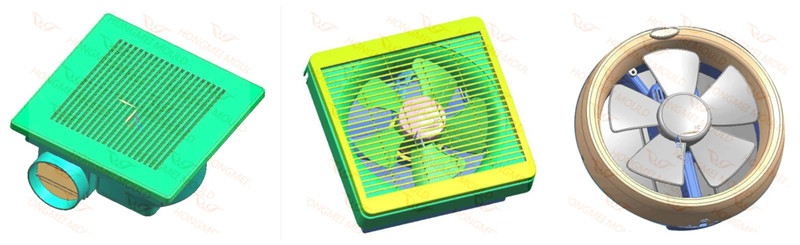

Plastic fan blade mould models

Design is the foundation of the product. A good design make the less of the repair work. Our design department has advanced CAD/CAE software, you can send us file like . We are the most suitable midwife of your great ideas! We can also put out a complete 2D and 3D mold blueprint according to the products provided by customers. You can send us the file in format of IGES, DXF, DWG, STP, X_T, PRT, etc or you could send us handwrite drawing or original sample is fine as well.

How To Control The Concentricity Of the Plastic Fan Blade Mould?

Concentricity of the Ventilador fan mold is made from two sides, cavity and core.

For the cavity of Ventilador fan mould, we make it by circular insert and embed in the mould base, which the circular insert can be machined by numerically controlled lathe.

For the core side of Ventilador fan mould, it consist of ejection plate and core insert. The ejection plate we make it as circular ring can be machined by numerically controlled lathe, and the core insert made it as circular column can be made in the same way. The leaves of the centrifugal fan on the core insert is made by slow wire cutting. Slow wire cutting machine cut the external surface 4 times to find the central of the core. The leaves made by wire cutting is very smooth, no need to do any polishing. There’s many other detail should concern to make the centrifugal fan mould, usually one of the process is wrong made, the mould is no longer useful.

Tips to improve your plastic fan blade mould polishing

Cleanliness. Keep your polishing area away from grinding dust and chips. Do not allow it to become a disorganized mess of loose stones and accessories.

Separate your stones. It is amazing that people dump a 220 gritstone in a box or can with a 600 grit stone. Sometimes they even mix up polishing sticks with different grits of the diamond. Let’s see, if you think you are polishing with a fine finish diamond and you get a coarser diamond piece mixed in,

what do you think will be the result?

Move your polishing area away from grinders and bead blasting equipment. For some reason, many shops just keep polishing away, right next to the surface grinders. All it takes is one stray piece of grinding grit to ruin your finish.

Use a microscope. Even though it is disheartening to see your work under a microscope, this is the only way to see the tiny scratches and imperfections. Plus, you can avoid rolling edges and damaging critical molding details

Don’t use unskilled help to do skilled work. Polishing is an art that takes a lot of time to learn. Don’t expect everyone to have the same ability when it comes to fine finishes or detail. Yet this often happens when owners view polishing as a nuisance.

Make a chart of the diamond paste colors. For some reason, some shops never write down which diamond is which grit and moldmakers are left trying to figure out the same problem over and over again. Figure it out and make a copy near the diamond compound!

Don’t think that “cross-hatching” is some kind of religion. Sometimes you see people who think you must only polish in one direction for each grit. Horizontal with a 400 grit and vertical with a 600 grit, for example. You can and should go back and forth in any direction you need to, just make sure you end up with the lines in the direction of the ejection-draw polish it. Your speed will dramatically increase once you get over this misconception.

About Hongmei

Hongmei Mould established in 2014 and specialized in making various plastic injection moulds. Hongmei company is located in Huangyan District, the beautiful "town of molds" in Zhejiang Province, China. It is convenient that it will take 30 minutes from Luqiao airport and 10 minutes from Taizhou railway station. Hongmei company specializes in developing all kinds of large-scale injection molds, especially in making automotive, home appliances and daily necessities molds, at the same time we provides one-stop service for mold semi-finished products processing. Our company cover an area of 5000 square meters and employee 86 workers which are skillfully.

Our Main Product

1.Household parts mould

2.Appliance parts mould

3.Automotive parts mould

4.Thin-wall parts mould

5.Industry parts mould

Our Equipment

Five-axis high-speed milling machines

Three-axis high-speed milling machines

CNC milling machines

Deep hole drilling machines

Large-scale milling machines

CNC engraving machines

Electric sparks (EDM)

wire cutter

These machines enable us to manufacture large-size moulds, complex moulds, deep cavity moulds, thin-wall moulds and high-precision moulds. The concept of high-quality, high-precision, high-tech, high-service-driven development continues to create miracles.

We anticipate your presence sincerely.

Contact Me