Packaging and delivery: injection mold, covered with anti-rust oil and PP film, put into a non-fumigation wood case; mold spare parts shipped together with mold from the port.

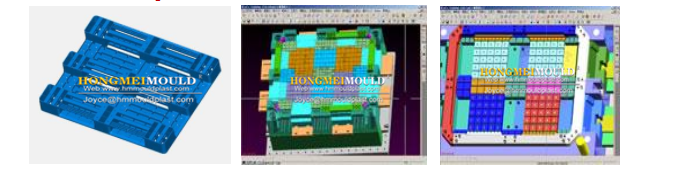

Design of Plastic Transport Pallet Mold

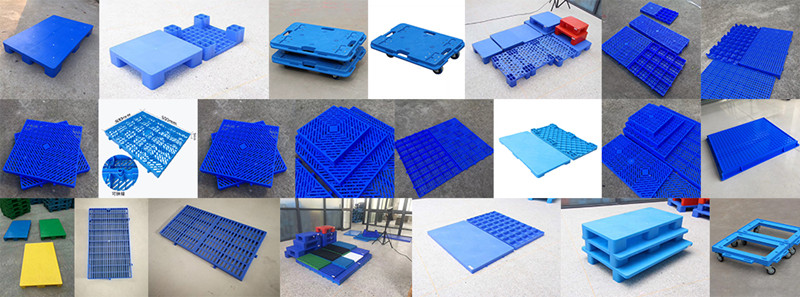

During the process of designing a plastic pallet, many things come into consideration. Things such as the purpose of the pallet and how it will be transported, stored, what industry will use the pallet.

All these considerations impact and contribute to the design, material, weight, and durability of a pallet. Once the design for the plastic pallet is in place, the mold will be made to make that exact design.

Additional pallet design consideration:

* Open/Closed decks

* Ventilation

* Sanitization

* Runners vs no runners

* Two-Way vs 4-Way entry

* Industry standards

* FDA approved

* Fire retardant

PP or PE plastic for the Plastic Transport Pallet Mold

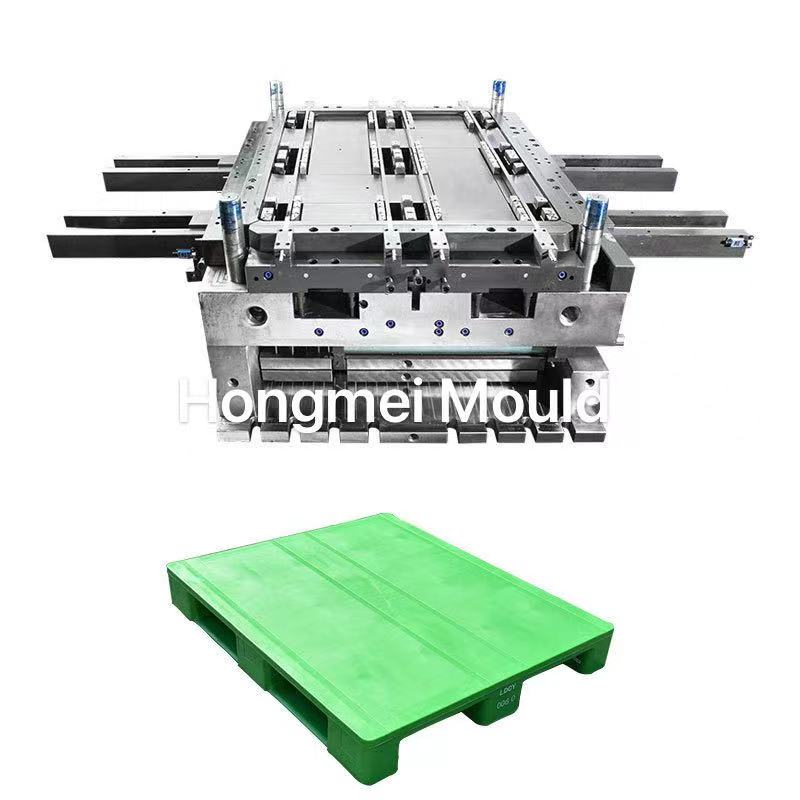

Plastic pallets are manufactured at an injection molding facility. But how do these individual designs come into existence, from planning to production? The path is complex but entirely necessary to ensure that the product is a success.

1. Main stages of pallet production

The process of designing and creating a plastic pallet has three main stages:

* pallet design

* pallet molding

* the final production of the pallet

In order to create the perfect plastic pallet, all of the functional details and design features need to be planned out to satisfy the pallet’s end-use and purpose.

For example, what material it will be made from if it’s going to be light or heavy-duty, stackable, rackable, or nestable?

Plastic Pallet Raw Materials Plastic Pellets Manufacturing - Source: https://commons.wikimedia.org/wiki/File:Banner-bg_3asih.jpg

These are just a few of the things that are important to consider when creating each individual pallet.

Though there are many different ways that pallets can be molded, the most common method used in our plastic pallets is high-pressure injection molding.

Pallet Mold Advangtage

1.The mould is designed with 3D modeling software

2.The mould is made by imported P20 and German etc.

3.The mould is designed by advanced hot Runner system and each cavity has independent temperature control and heater system.

4.The mould surface is plated by reliable hard chrome.

5.The mould cavity is replaceable,so that the label top can be changed.

6.All the parts are manufactured with CNC equipments.

Featured with light-weight and solid quality, beautiful appearance, and durable performance, it is easy to clean, anti-static and recoverable, it will be your good assistant.

Plastic Double Face Transport

Plastic Double Face Transport