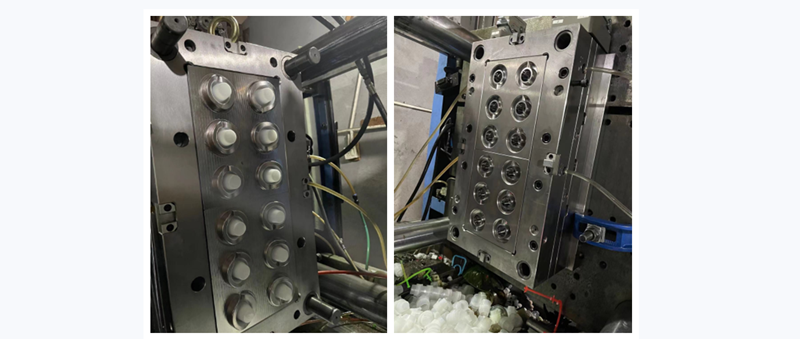

Plastic Milk Bottle Cap Mould

Mould Name: Cap/PET Preform Mould

Product Size: PCO28mm

Product Description: 2g caps for water packaging industry

Mould Cavity: 72 Cavity

Mould Size: 1320*620*759mm

Suitable Machine: DKM-600HH

Mould Main Material: S136 stainless steel with HRC48-50 (ASSAB )

Mould Injection System: hot runner Gate(Anole brand)

Mould Ejection System: stripper

Mould Cycle Time: 7 Seconds

Mould Running: 5M

Delivery Time: 60 working days

Mould Features

1. Meet high-quantity productivity ,26000-30000 PCS/hour

2. Full hot runner system with Germany heater

3. Interchangeable core and cavity,easy for maintainence

4. DKM600HH high speed injection machine, cycle time reach 9s

5. With Keba PLC, realize humaniz

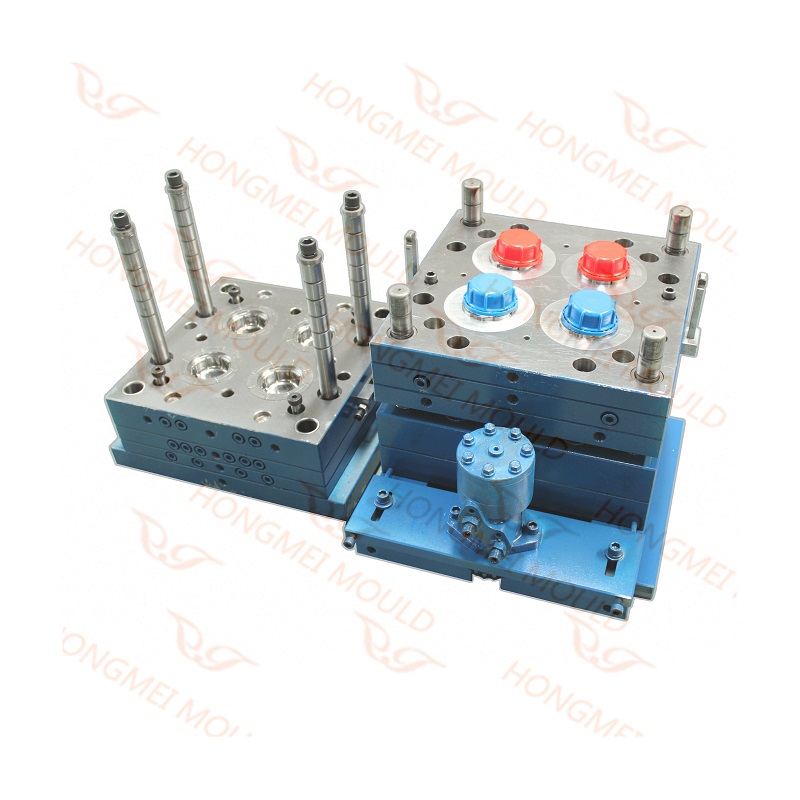

plastic cap mould and PET preform mould. For the cap mould, we could make flip-top cap mould, water cap mould, Juice cap mould, spray cap mould which could suit for different bottle size. We could also make PET preform mould with multi-cavity for 30ml until 5gallon bottle capacity.

If you have new plan to invest into water packaging industry, welcome to contact us, we could supply high quality plastic production line, include cap injection molding line, PET preform injection molding line and also bottle blowing line. We are the direct mould and injection molding machine manufacturer, we could offer favorable price with convenient service.

How to design screw on a bottle flip top cap,lid and closure mould

Undercuts on the Inside of the cap

Undercuts on the Inside of the cap are usually

Inside threads,

snap-on ribs (for cap, closure or lids of containers), or

major undercuts that are part of the product shape.

Inside Threads on cap

Inside threads usually occur in cap but also may be designed in many technical products such as plastic pipe hardware, etc.

The planned method of manufacture (molding, or machining after molding) should be considered.

The cap mould could be much simpler (and considerably less costly) if the cap is threaded after molding; the designer should be aware of the production quantities required.

As we stated before,it is more important to arrive at the lowest total cost product than at the most elegant method of manufacture.

If the thread must be molded, we again have two choices of how to remove the product from the core: by unscrewing or by stripping.

Unscrewing

Unscrewing Threads are usually designed to standards and, as a rule, consist of more than one pitch (length).

In many screw caps for bottles Jars, tooth paste tubes, and technical closures, two to six pitches are quite common.

Within reasonable limits, there is usually no problem with the number of turns that are required to unscrew the cap,except that, the more turns,the larger will be the actuating mechanisms required in conventional unscrewing cap molds.

Also, more turns mean longer products, more plastic, more molding, and more unscrewing time (longer cycles). In many closures, it has been shown that a thread length of one or two pitches is sufficient for good holding power and tightness of the closure.

This is an area the cap mould making designer must carefully consider because the wrong decision can become very costly in the long run.

There are several unscrewing methods; however, all depend on features that are not part of the product design but which must be indicated on the cap drawing.

stripper ring; the cap must be held so that it can be unscrewed away of the core, and retracts.

This usually ratchets on the underside of the wall of the screw cap,In one system, the cap requires ribs or other projections on the outside, where an external unscrewing device can engage to grab the closures to remove them from the cap mold cores.

The design of these aids for unscrewing should be discussed with the mold designer for this project.

From the foregoing discussion, it becomes clear that any unscrewing method requires either complicated cap moulds or special machines.

The molding cycles are also slower than comparable products that need not be unscrewed.

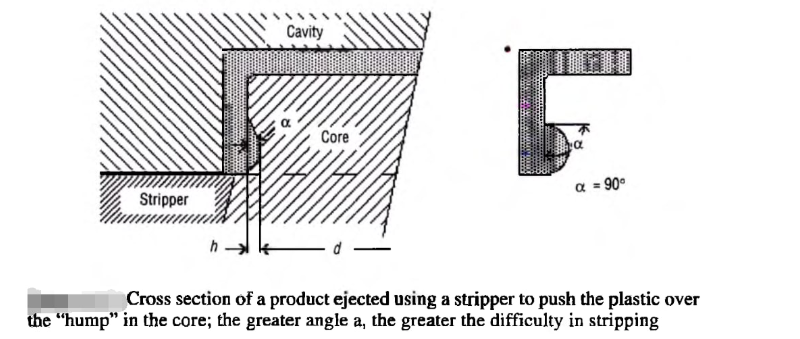

Cross section of a product ejected using a stripper to push the plastic over the “hump” in the core; the greater angle IS,the greater the difficulty in stripping quantity applications, the core could be also removable from the mold and unscrewed from the product outside of the mold, by hand or by using fixtures.

Stripping ejection (force ejection)

The plastic cap mould designer must consider whether the plastic cap can be stripped from the threads.

Stripping is the easiest (and often the lowest cost) solution for ejecting the cap or closer; however, the ease of stripping depends on many equally important factors.

The theory of stripping is quite simple. As the cap mould opens, and after the cavity has moved away from the core side, the ejection starts, caused by the stripper moving forward.

In doing so, the plastic cap is pushed over the hump in the core; this causes the plastic to expand so that the portion that is inside the groove in the core can slip out of the groove.

Plastic Milk Bottle Cap Mould

Plastic Milk Bottle Cap Mould