Customized the mould according to your sample.

Quality control on Plastic Purifier Filter Mould

Strict quality control has been applied on every stage from incoming materials, manufacturing process, finished molds to delivery.

1. Main QC Procedure:

2. Main QC Equipment

*Mutual Development

The Supplier of Home Appliance Mould

At the same time, the color, feel, precision and wall thickness of the housing of household appliances put forward new requirements. With the acceleration of product updates, the emergence of new products, the overall shell of home appliances towards a thin, light, fine direction of development.

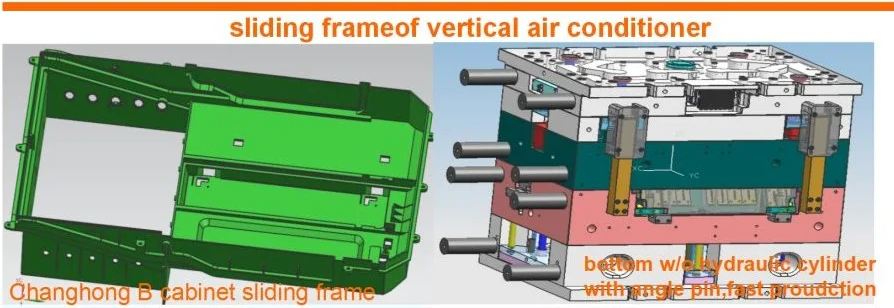

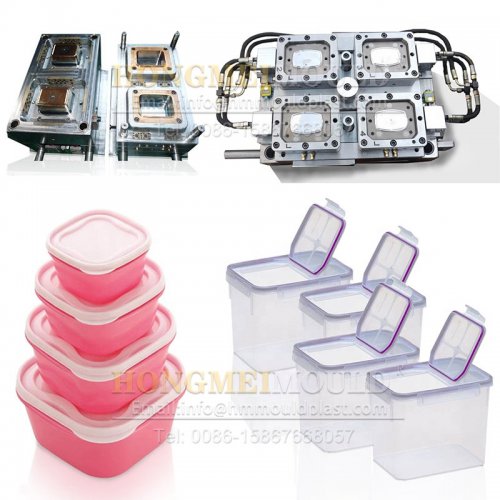

Hongmei Mould introduced a variety of imported high-precision processing equipment, five-axis CNC processing equipment, dedicated to electrical shell mold processing, air conditioning parts mold, air conditioning shell mold processing. The surface machining accuracy of household appliances manufactured with high-speed milling and finishing can reach 0.01mm.

Hongmei Mould also applies hot current technology and gas-assisted technology to the molding of home appliances mould. Most home appliance mold use hot-flow technology, and we are also able to use gas-assisted technology on TV housings, washing machine casings and thick-walled plastic part molds. Gas-assisted injection molding has low injection pressure, small product warping deformation, good surface quality, wall thickness difference easy to form the advantages of the product, in order to ensure product quality under the premise can greatly reduce costs.

Hongmei Mould professional design, production of various types of home appliance mold, we are a number of home appliance mold suppliers around the world. We specialize in the production of refrigerators and washing machine molds, and we can analyze the feasibility of molding plastic appliance parts and provide a variety of mold design solutions. Every year, We have a large number of home appliance mold exports, including air conditioning parts mold, air conditioning shell mold, air conditioning component mold, liquid crystal display shell mold, refrigerator mold, and other household appliances mold.

If you would like to learn more about home appliance molds or need to purchase such molds please contact us, we will provide you with the perfect solution.

Plastic Purifier Filter Mould Packing and Delivery

Mould shipment Details

- Quality inspection of plastic mold installation:

Complete inspection of plastic mold to ensure the continuity of mold structure and the standard of parts. The project manager and quality inspection personnel shall inspect the plastic mould according to the company's standard, so as to ensure the quality of the products. Once the problem is found, it can be corrected immediately, and effectively prevent the occurrence of errors. In addition, we continuously test the cooling system, hydraulic oil duct system and hot runner system of plastic mold

Checking before mould delivery

1. After confirming the sample of customer, our manager will inform our team leader to check the mould. Including the 3d mould design, customer's requirements and mould trial problem.

2. Our inspector will according the files above to check the mould.

3. If our customer need the water channel drawings and oil channel drawings, we will print for you, of course we could provide mould water transport pictures.

4. After all the detailed checking no question, then we will inform our team leader to packing the mould.

- Mould specification

1. Team leader will fill in the instruction

2. Packing all the mould accessories into a wooden case

3. Prepare mould trial report, mould using instruction, mould temperature control box instruction and quality certification to customer.

- Mould Packing

1. Cleaning the cavity and core, no iron filings

2. Spraying the antirust paint inside and outside

3. Wrapped with the plastic film

4. Putting into a wooden case or wooden pallet

How to choose the home applian

How to choose the home applian

How to make a car front bumper

How to make a car front bumper

Multi Cavity Plastic Hanger Mo

Multi Cavity Plastic Hanger Mo

The Manufacturing Process of C

The Manufacturing Process of C

Plastic Crate Injection Mold M

Plastic Crate Injection Mold M

Plastic Purifier Filter Mould

Plastic Purifier Filter Mould

Plastic Rotating Spin Mop Buck

Plastic Rotating Spin Mop Buck

Plastic Fan Blade Mould

Plastic Fan Blade Mould

Professional Plastic Stool Mol

Professional Plastic Stool Mol

Technical Analysis of Plastic

Technical Analysis of Plastic

Differential Analysis of Two-c

Differential Analysis of Two-c

How to Make a Plastic Turnover

How to Make a Plastic Turnover

The better the plastic mould i

The better the plastic mould i

What are the injection moulds

What are the injection moulds

Mold Manufacturer of Plastic T

Mold Manufacturer of Plastic T

Injection Mold for Huangyan Co

Injection Mold for Huangyan Co

Mold for garbage bin of daily

Mold for garbage bin of daily

Analysis of Household Applianc

Analysis of Household Applianc