How to choose the home appliance product surface finish?

When designing a part for injection molding,it is important to keep in mind the relationships between surface finish, moldability, cost and lead time.

If the part will not be visible to the end user,you will probably choose to specify either PM-F0 or PM-F1 using the drop-down menus on your ProtoQuote (see sample). But manytimes your design will require a more cosmetic surface finish. In these cases there are two key things to keep in mind:

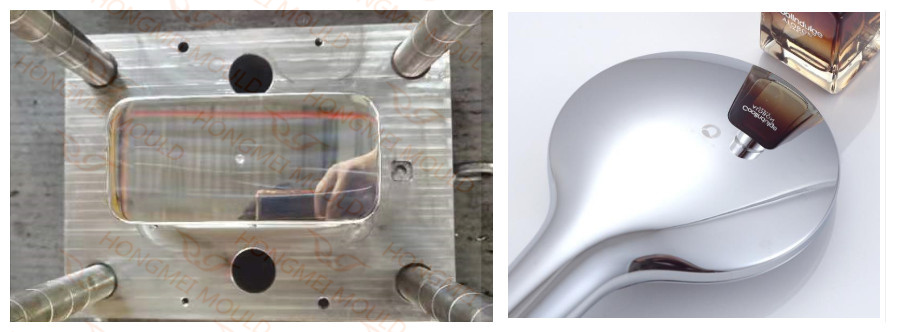

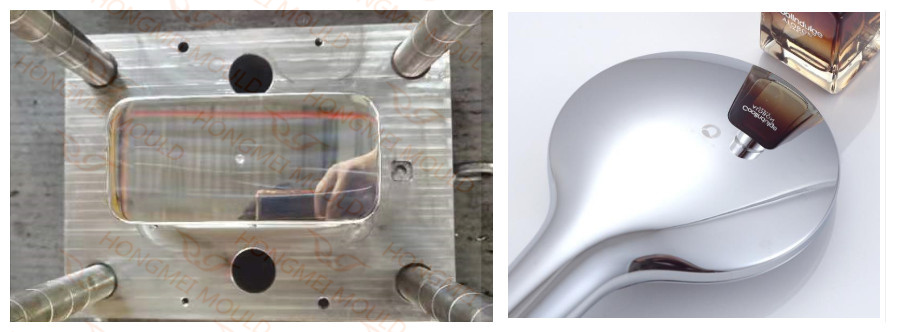

Polishing: Smoother part surfaces are achieved using manual mold polishing techniques. Consider a part with tall,thin and curved rabs .in this case you should consider a significant cost increase bcs it is very time consuming to polish deep,narrow slots in the mold .And such lenthy polishing times may also affect the lead time for the parts, potentially making it impossible for protomold to accept your order for our 5-day turn.

Texturing: giving the line-of-sight nature of bead blasting,it may not be possible to texture the sides of minemally drafted ribs on a part bcs the mold surfaces may be acceptable.in addition, if the wall of the parts are textured it may have an adverse effect on the ability of the part to release from the mold,potentially resulting in unsightly “drag marks”.For these reasons we recommend that texture be specified only on areas of the part that are drafted at least 2-3 degrees.And in fact if your part have not sufficient draft you proto quote maynot even offer these textures as options for you to select.

An SPI Mold Finish Comparison Kit can be ordered directly from SPI or from other supplies such as DME. This kit consists of 12 disks polished to the appropriate level and is a handy tool for measuring or checking on the finish level.

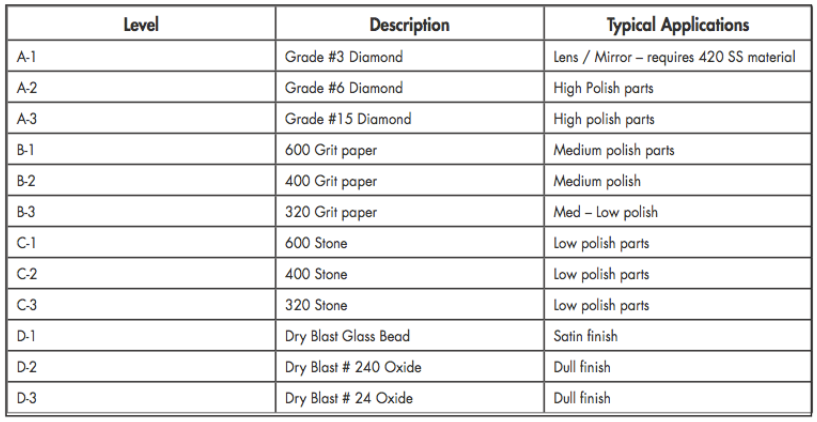

The level of finish of the mold will frequently be determined by the product that will eventually emerge from the mold. “It depends on the customer request,” said Cipriano.

“We use different finish levels because that affects the parts that will come out of the mold. For example if you needed to do something in polypropylene and the request is for a finish for an optical finish, that is impossible because of the material will not handle that finish.” The level of finish must match the material that will come out of the mold.

Hongmei mould company will according to product character and make different polish degree.

How to choose the home applian

How to choose the home applian

How to make a car front bumper

How to make a car front bumper

Multi Cavity Plastic Hanger Mo

Multi Cavity Plastic Hanger Mo

The Manufacturing Process of C

The Manufacturing Process of C

Plastic Crate Injection Mold M

Plastic Crate Injection Mold M

Plastic Purifier Filter Mould

Plastic Purifier Filter Mould

Plastic Rotating Spin Mop Buck

Plastic Rotating Spin Mop Buck

Plastic Fan Blade Mould

Plastic Fan Blade Mould

Professional Plastic Stool Mol

Professional Plastic Stool Mol

Technical Analysis of Plastic

Technical Analysis of Plastic

Differential Analysis of Two-c

Differential Analysis of Two-c

How to Make a Plastic Turnover

How to Make a Plastic Turnover

The better the plastic mould i

The better the plastic mould i

What are the injection moulds

What are the injection moulds

Mold Manufacturer of Plastic T

Mold Manufacturer of Plastic T

Injection Mold for Huangyan Co

Injection Mold for Huangyan Co

Mold for garbage bin of daily

Mold for garbage bin of daily

Analysis of Household Applianc

Analysis of Household Applianc