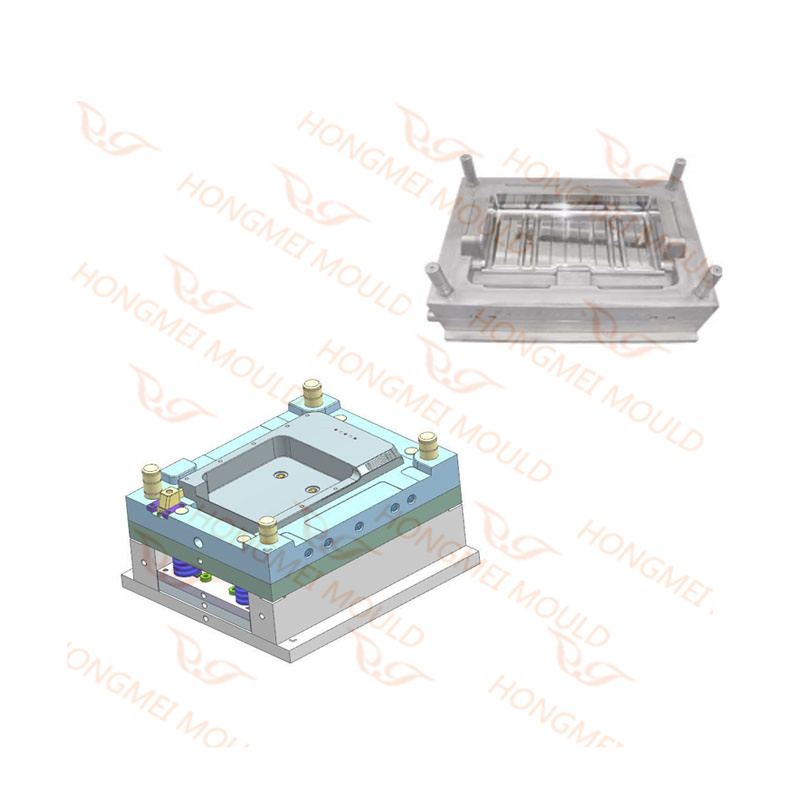

Mould Name: Wall-mounted water purifier Mold

Part size: 600X400X80

Mould cavity No.: 1 cavity

Mould size: 900X650X500

Suitable Injection machine: 530 Ton

Mould Material: NAK80 for core and H13 cavity,slider. S50C for mold base

Mould feeding gate system: Hot runner

Mould Ejection system: Lefter and ejector

Mould cycle time: 40 Seconds

Mould life time: 600k Shots

Mould guarantee: Five year warranty and maintance service supports

Mould Package: Painted with anticorrosive paint and wrapped with plastic film by export standard wooden case.

Mould lead time: 45 days for T1 after deposit

Mould payment: 30% deposit,70% before shipment

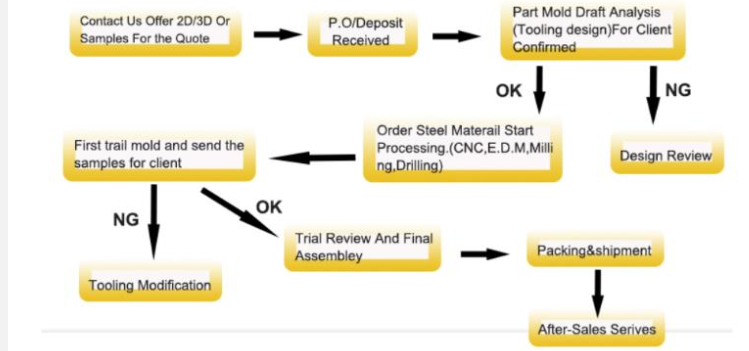

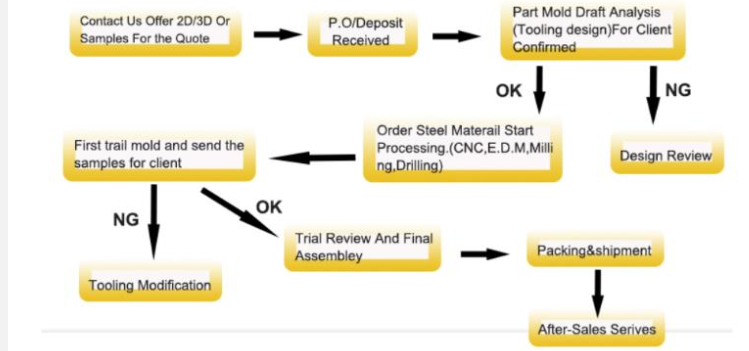

How to place an order?

Our company not only sells Portable Air Cooler Mold, Mini Juice Blender Mold, Bulkhead Lamp Plastic Mold from production to customers, but also pays more attention to matching them with the most suitable users. So far our products have been exported to all over the world We always follow the management principles of science first, quality first, and customer first, with the goal of promoting product structure optimization and production standardization. We will sincerely cooperate with friends from all walks of life with our excellent products and perfect service, and welcome new and old customers to visit our company, discuss cooperation and work together for common benefit.

Only need you sent us your 3D or CAD part file, we give you price with 20% discount than other supplier.

Before design the water purifier molds, there are a lot of issue should be take into consideration, such as the demoulding angle,ejector,feeding gate system, cooling water system and how to make the parting line. We have completely solution and experience for making perfect water purifier molds with high quality.

Based on our many years of experience, not only learning the advanced level of the industry, but also through our own repeated experiments to compare and improve, we promise that our Injection Plastic Wall Mounted Water Purifier Cabinet Mould has the most reliable and stable performance. We consistently regard quality and service as the company's goal. With a rigorous work style, we will achieve high-quality quality and perfect service without compromise, so that customers feel that choosing us is to choose peace of mind. Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers.

Processing information

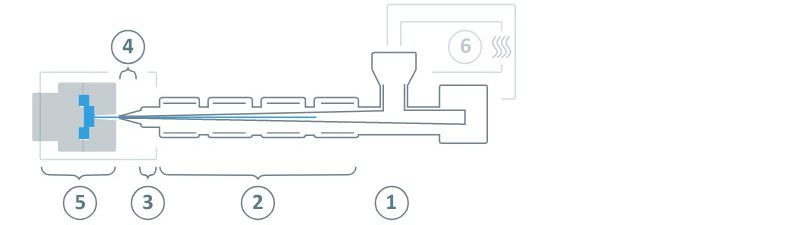

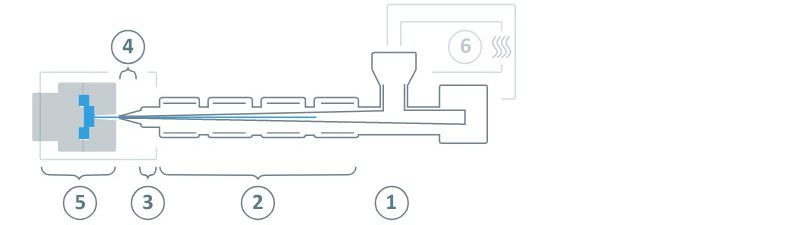

The listed values are recommendations. Higher values should be used for higher glass loadings. We recommend only de-humidifying or vacuum dryers. Extensive drying can cause filling problem and surface defects.

1 Feed section 60-80℃

2 Temperature zone 1 - zone 4 260-300℃

3 Nozzle temperature 270-310℃

4 Melt temperature 280-300℃

5 Mold temperature 80-100℃

Holding pressure, spec. 300-800 bar

Back pressure, spec. 50-150 bar

Injected speed medium to high

Screw speed 8-15m/min

6Drying time 0-4H

Drying temperature(τ ≤ -30°C) 80℃

Processing moisture 0.02-0.1%

*Physical properties Value Unit Test Standard

density 1360 kg/m³ ISO 1183

*Mechanical properties Value Unit Test Standard

tensile modulus(1mm/min) 9700 Mpa ISO 527 2/1A

tensile stress at break(5mm/min) 170 Mpa ISO 527 2/1A

tensile strain at break(5mm/min) 2.1 % ISO 527 2/1A

flexural modulus(23℃) 9000 Mpa ISO 178

flexural strength(23℃) 280 Mpa ISO 178

charpy notched impact strength @ 23℃ 23 KJ/m³ ISO179/1eA

*Thermal properties Value Unit Test Standard

DTUL @ 1.8 Mpa 252 ℃ ISO 75-1/-2

20L Paint Barrel Lid molding

20L Paint Barrel Lid molding

Plastic Paint Pail Mould

Plastic Paint Pail Mould

Wall-mounted water purifier Mo

Wall-mounted water purifier Mo

High Quality and High Efficien

High Quality and High Efficien

Plastic Air Conditioning Cover

Plastic Air Conditioning Cover

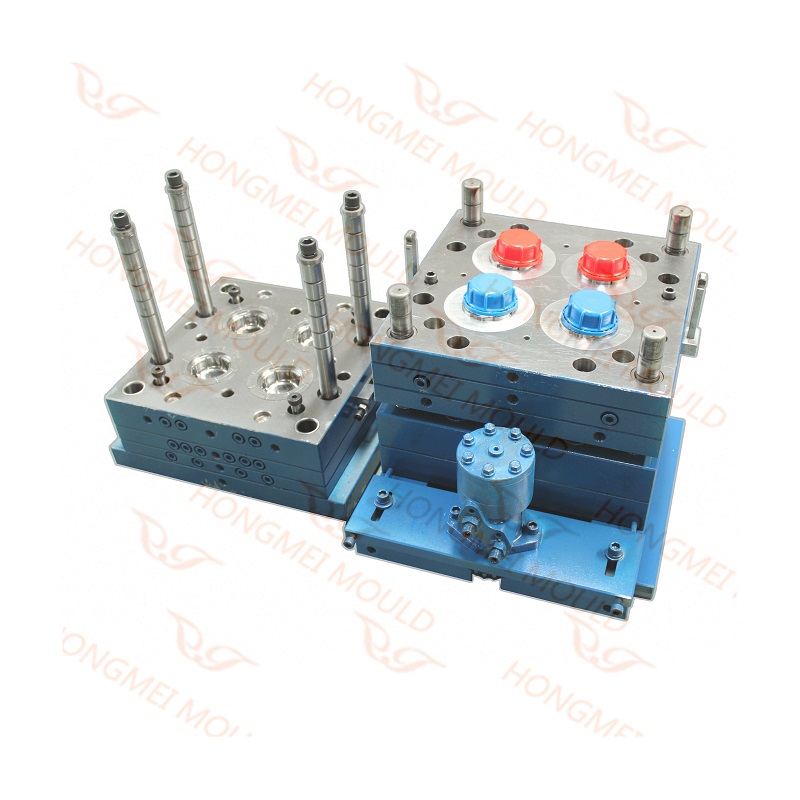

Plastic Milk Bottle Cap Mould

Plastic Milk Bottle Cap Mould

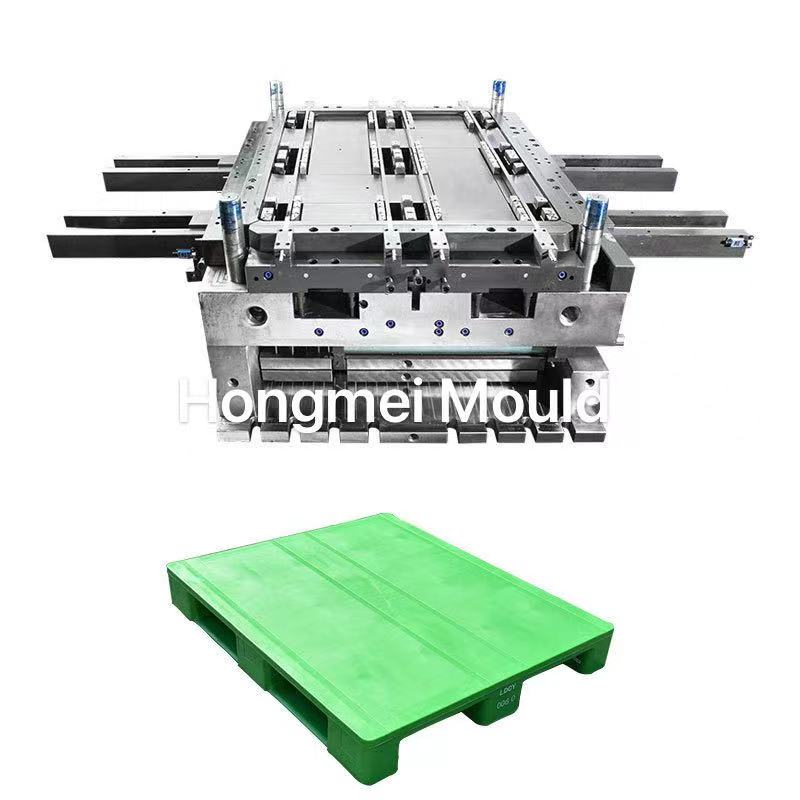

Plastic Double Face Transport

Plastic Double Face Transport

Hongmei Large Trash Bin Mold

Hongmei Large Trash Bin Mold

Plastic Car Logo Injection Mou

Plastic Car Logo Injection Mou

Plastic Injection Washing Mach

Plastic Injection Washing Mach